日本齿轮

Nippon Gear

Nippon Gear

/日本齿轮

Nippon Gear

/日本齿轮

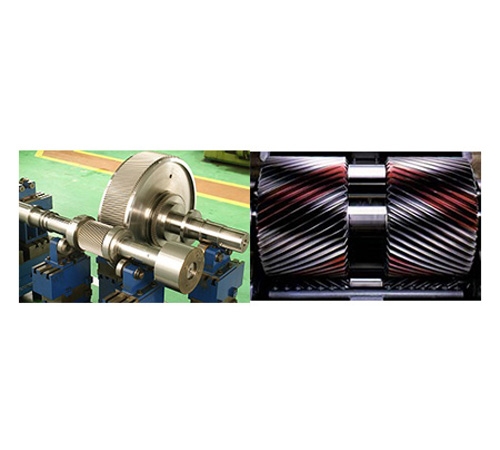

High precision cylindrical gear

A gear grinder can be used to grind high-speed cylindrical gears with multiple teeth and a small module on the tooth surface to ensure jis0 or higher tooth accuracy. As a result, even when the circumferential speed is 100 m / s or higher, smooth and quiet engagement can be achieved, so it is used in compressors and generators that require a large number of high-speed rotations.

Gears with helical gears with different torsional directions processed at two positions of the same shaft are called double helical gears. The tooth surface is polished with a gear grinder, which is used for rotating equipment that needs high-speed rotation. Due to its coaxial left-right distortion, it offsets the generated thrust, which is a favorable gear for design and use.

Table of grindable size of teeth:

Gears with helical gears with different torsional directions processed at two positions of the same shaft are called double helical gears. The tooth surface is polished with a gear grinder, which is used for rotating equipment that needs high-speed rotation. Due to its coaxial left-right distortion, it offsets the generated thrust, which is a favorable gear for design and use.

Table of grindable size of teeth:

|

Gear grinder |

|

|

Maximum addendum circle diameter |

2,000mm |

|

Maximum tooth width (spur gear) |

2,020mm |

|

Max / min pitch |

Model 45/1 |

|

Max / min number of teeth |

No input restrictions |

|

Maximum torsion angle |

-45°〜+120° |

|

Maximum workpiece weight |

14,000kg |

|

Hob plate |

|

|

Maximum addendum circle diameter |

2,000mm |

|

Maximum tooth width |

1,760mm |

|

Maximum pitch |

Mod.30 |

|

Max / min number of teeth |

No input restrictions |

|

Maximum hob diameter |

385mm |

Back

Back